Green Energy

- Condenser – Air Extraction Equipment ( 1 Of 3 )

CONDENSER – AIR EXTRACTION EQUIPMENT - Turbines are designed for a particular operating conditions like steam inlet pressure, steam inlet temperature and turbine exhaust pressure/ exhaust vacuum, which affects the performance of the turbines in a...

- Deaerator ( Part 1 )

DEAERATOR ( PART 1 ) FUNCTION-The function of the deaerating heater is to remove dissolved non-condensable gases and to heat boiler feed water. A deaerating heater consists of a pressure vessel in which water and steam are mixed in a controlled manner....

- Can Your Boiler Feed Pump Handle A Deaerator Pressure Transient?

Can Your Boiler Feed Pump Handle a Deaerator Pressure Transient? “This is part of an article talking about the importance of DA and BFP positions at power plant “ In a typical steam power plant, the boiler feedwater (BFW) pump takes suction...

- Steam Turbine & Generator Arrangement

STEAM TURBINE ARRANGEMENT The live steam enters the HP turbine through the main stop valves (MSV) and the main control valves (GOVERNORS). After expansion in the HP turbine, the steam is let to the cold reheat line via power assisted check valve. The...

- Boiler Control Theory (feed Water Control)

Boiler Control Theory (Feed water Control) The feed water is controlled to keep the drum level . Water-level controls continuously monitor the level of water in a steam boiler in order to control the flow of feed water into the boiler and to protect...

Green Energy

Air Ejectors (2 of 3)

Air Ejectors (2 of 3)

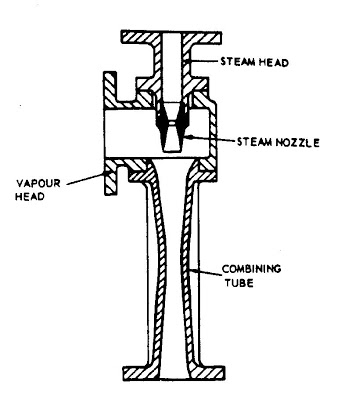

-An air ejector or steam ejector is a device which uses the motion of moving fluid (Motive Fluid) to transport another fluid (Suction fluid). It is has a wide range of application in steam ejector in boiler condenser, fresh water generator and in priming the centrifugal pump.

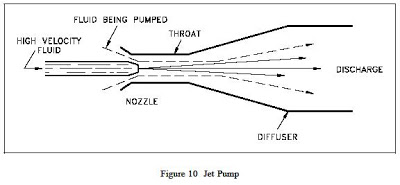

-It works on the principle of convergent /divergent nozzle as it provides the venturi effect at the point of diffusion as the tube gets narrows at the throat the velocity of the fluid increases and because of the venturi affect it pressure decreases, vacuum will occur in the diffuser throat where the suction line will be provided.

-The operating medium of an air ejector can be either high-pressure gas or liquid. This is passed through a nozzle and the pressure energy is converted into velocity energy. The high-velocity fluid aspirates the air and the non-condensable gases and the mixture is projected into a diffuser which reconverts the velocity energy into pressure energy.

-Steam is suitable operating medium and is used in the steam-jet air ejector. The steam consumption is controlled by the compression ratio of the air and this factor influences the decision to adopt either single or multiple stage ejectors for a particular condition.

-To meet the requirements when raising vacuum a starting ejector is provided. This is high capacity, high steam consumption ejector, of single stage and without an after condenser.

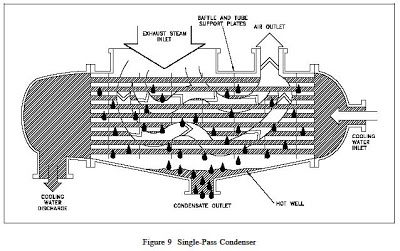

-A main air ejector with standby unit is usually provided for normal operation. The heat in the operating steam is partially recovered in the condensate which flows through the inter and after coolers.

-If an installation is to operate with a direct cooling system, as is provided by the sea or a river, vacuum as high as 29.2 in.Hg would be expected during the winter months.

-A cooling tower installation will operate at a slightly poorer vacuum than a direct cooled station and this vacuum can usually be handled by a two-stage ejector.

- Condenser – Air Extraction Equipment ( 1 Of 3 )

CONDENSER – AIR EXTRACTION EQUIPMENT - Turbines are designed for a particular operating conditions like steam inlet pressure, steam inlet temperature and turbine exhaust pressure/ exhaust vacuum, which affects the performance of the turbines in a...

- Deaerator ( Part 1 )

DEAERATOR ( PART 1 ) FUNCTION-The function of the deaerating heater is to remove dissolved non-condensable gases and to heat boiler feed water. A deaerating heater consists of a pressure vessel in which water and steam are mixed in a controlled manner....

- Can Your Boiler Feed Pump Handle A Deaerator Pressure Transient?

Can Your Boiler Feed Pump Handle a Deaerator Pressure Transient? “This is part of an article talking about the importance of DA and BFP positions at power plant “ In a typical steam power plant, the boiler feedwater (BFW) pump takes suction...

- Steam Turbine & Generator Arrangement

STEAM TURBINE ARRANGEMENT The live steam enters the HP turbine through the main stop valves (MSV) and the main control valves (GOVERNORS). After expansion in the HP turbine, the steam is let to the cold reheat line via power assisted check valve. The...

- Boiler Control Theory (feed Water Control)

Boiler Control Theory (Feed water Control) The feed water is controlled to keep the drum level . Water-level controls continuously monitor the level of water in a steam boiler in order to control the flow of feed water into the boiler and to protect...