Green Energy

Water-level controls continuously monitor the level of water in a steam boiler in order to control the flow of feed water into the boiler and to protect against a low water condition which may expose the heating surfaces with consequent damage. The control may be float operated but modern plant will have conductivity probes. The probes will be fitted in pads or standpipes on the crown of the shell or drum and enclosed in a protection tube which will extend to below the lowest water level.

(1) One element control

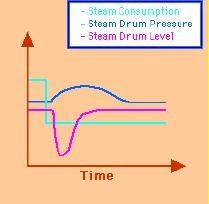

Similarly, when the steam consumption reduces suddenly, the drum pressure rises immediately and the steam bubbles in the water shrink. This leads to a sharp momentary decrease in the drum level. This initial decrease in the steam drum level is called shrink.

In a conventional one-element control strategy the output of a level controller cascades into a flow controller. Consider now the use of a conventional one-element control strategy to control the steam drum level. As the drum level increases the controller reduces the feed water supply. And similarly, if the drum level decreases the controller increases the feed water supply. Let us assume that the steam consumption increases suddenly. Due to the swelling effect the steam drum level will rise initially and then decrease. The controller will initially reduce the feed water supply. This will in effect reduce the water inventory and after the swell effect the water drum level will drum significantly.

This is a disadvantage of one element control system , therefore we use only this system structure at (20 to 25 % load) , and we have to take care of drum level by controlling the start up blow off valves. So, to eliminate such this problem , another control scheme is applied to eliminate the drawbacks of one-element control at higher loads.

(2) Three element control

Three element control using the followings is applied during the normal operation (> 20-25% boiler load )

- Drum level

- Main steam flow

- Feed water flow

Now, let us assume that the steam consumption increases suddenly. As the steam consumption increases the feed forward signal increases the feed water supply to the steam drum. Due to the swell effect the level controller reduces the feed water supply. The net effect of the three-element level control scheme changes the feed water supply appropriately and reduces the effect of swell on the drum level. Thus, the three-element level control strategy provides a more stable drum level control.

- Boiler (master Fuel Trip)

Steam Generator ( boiler ) is very important equipment at thermal power units , Boiler is the steam supply for the unit to rotate the turbine's rotor , hence produce electricity at Generator's stator. Boiler usually equipped with solar and Main...

- Deaerator ( Part 2 )

DEAERATOR ( PART 2 ) OPERATION PROCEDURES ** Pre-start checks and operations(1) Vent valve shall be wide open.(At low load start, it may be necessary to throttle valve slightly to increase the operating pressure, but vent valve not to be fully close...

- Boiler Steam System

Boiler STEAM SYSTEM -The boiler Steam system consists of SUPERHEATER, REHEATER AND BLOWDOWN SYSTEM 1) SUPERHEATER-The saturated steam from the drum flows into three stages of superheaters. Steam is superheated up to rated temperature through primary,...

- Boiler Water System

Boiler Water SYSTEM We talked before about HITACHI Boiler Air and Flue gas system, we mentioned the characteristics of the boiler Air and flue gas & Parameters of operating Steam and waterAt this article we will make a focus on Water system at boiler....

- Swirling Problem At Boiler’s Start-up

At boiler’s start-up, one should take care of water swirling at boiler’s Drum, especially when you start at Cold Start Mode. Swirling at cold start, makes water level fluctuates very much at the Drum. Therefore it can trip the boiler with Drum...

Green Energy

Boiler Control Theory (Feed water Control)

Boiler Control Theory (Feed water Control)

The feed water is controlled to keep the drum level .

Water-level controls continuously monitor the level of water in a steam boiler in order to control the flow of feed water into the boiler and to protect against a low water condition which may expose the heating surfaces with consequent damage. The control may be float operated but modern plant will have conductivity probes. The probes will be fitted in pads or standpipes on the crown of the shell or drum and enclosed in a protection tube which will extend to below the lowest water level.

With watertube boilers the control of the water level needs to be precise and sensitive to fluctuating loads due to the high evaporative rates and relatively small steam drums and small water content.

(1) One element control

One element control using only the drum level is applied during the low load (< 20-25% boiler load).

before we talk about the control theory of one element control , we have to show the (SHRINK and SWELLING) phenomena which is happened at boiler drum ,whenever you start firing the boiler:-

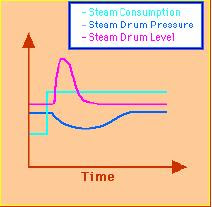

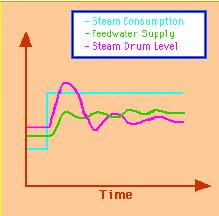

To illustrate the shrink and swell effect in a steam drum let us consider a sharp increase of steam consumption. With the sudden increase in the steam consumption the steam drum pressure drops immediately. With the sudden drop in the pressure the steam bubbles in the water wall and the drum swell and results in a sharp momentary increase in the drum level. After the pressure stabilizes the drum levels behaves in a conventional manner. This initial increase in the level is called swell and it is unique to the steam drum.

Similarly, when the steam consumption reduces suddenly, the drum pressure rises immediately and the steam bubbles in the water shrink. This leads to a sharp momentary decrease in the drum level. This initial decrease in the steam drum level is called shrink.

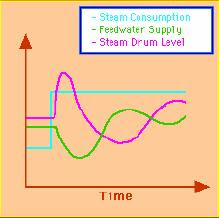

In a conventional one-element control strategy the output of a level controller cascades into a flow controller. Consider now the use of a conventional one-element control strategy to control the steam drum level. As the drum level increases the controller reduces the feed water supply. And similarly, if the drum level decreases the controller increases the feed water supply. Let us assume that the steam consumption increases suddenly. Due to the swelling effect the steam drum level will rise initially and then decrease. The controller will initially reduce the feed water supply. This will in effect reduce the water inventory and after the swell effect the water drum level will drum significantly.

This is a disadvantage of one element control system , therefore we use only this system structure at (20 to 25 % load) , and we have to take care of drum level by controlling the start up blow off valves. So, to eliminate such this problem , another control scheme is applied to eliminate the drawbacks of one-element control at higher loads.

(2) Three element control

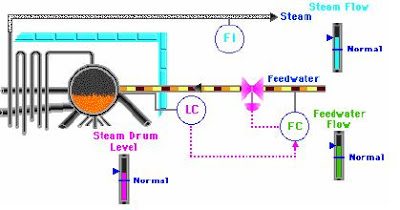

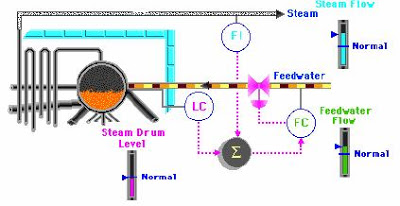

Three element control using the followings is applied during the normal operation (> 20-25% boiler load )

- Drum level

- Main steam flow

- Feed water flow

In order to handle the situation, the steam flow rate should also be considered for drum level control. It can be done by adding the steam flow rate as a feed forward signal to the output of the level controller. Hence, the supply of the feed water flow is compensated for changes in the steam flow rate demand. With this strategy as the steam flow rate changes the demand for the feed water flow rate also changes in the right direction and minimizes the effect of shrink and swell on the drum level.

Now, let us assume that the steam consumption increases suddenly. As the steam consumption increases the feed forward signal increases the feed water supply to the steam drum. Due to the swell effect the level controller reduces the feed water supply. The net effect of the three-element level control scheme changes the feed water supply appropriately and reduces the effect of swell on the drum level. Thus, the three-element level control strategy provides a more stable drum level control.

- Boiler (master Fuel Trip)

Steam Generator ( boiler ) is very important equipment at thermal power units , Boiler is the steam supply for the unit to rotate the turbine's rotor , hence produce electricity at Generator's stator. Boiler usually equipped with solar and Main...

- Deaerator ( Part 2 )

DEAERATOR ( PART 2 ) OPERATION PROCEDURES ** Pre-start checks and operations(1) Vent valve shall be wide open.(At low load start, it may be necessary to throttle valve slightly to increase the operating pressure, but vent valve not to be fully close...

- Boiler Steam System

Boiler STEAM SYSTEM -The boiler Steam system consists of SUPERHEATER, REHEATER AND BLOWDOWN SYSTEM 1) SUPERHEATER-The saturated steam from the drum flows into three stages of superheaters. Steam is superheated up to rated temperature through primary,...

- Boiler Water System

Boiler Water SYSTEM We talked before about HITACHI Boiler Air and Flue gas system, we mentioned the characteristics of the boiler Air and flue gas & Parameters of operating Steam and waterAt this article we will make a focus on Water system at boiler....

- Swirling Problem At Boiler’s Start-up

At boiler’s start-up, one should take care of water swirling at boiler’s Drum, especially when you start at Cold Start Mode. Swirling at cold start, makes water level fluctuates very much at the Drum. Therefore it can trip the boiler with Drum...