Green Energy

- Boiler Drum Roles

BOILER DRUM ROLES - Steam drums are used on recirculating boilers that operate at subcritical pressures. The primary purpose of the steam drum is to separate the saturated steam from the steam-water mixture that leaves the heat transfer surfaces...

- Boiler Steam Purity

BOILER STEAM PURITY - It is important that the steam leaving the boiler drum should be free from impurities which could be deposited in the superheater or the turbine. - Such impurities may arise from two distinct causes, one being the property...

- Deaerator ( Part 2 )

DEAERATOR ( PART 2 ) OPERATION PROCEDURES ** Pre-start checks and operations(1) Vent valve shall be wide open.(At low load start, it may be necessary to throttle valve slightly to increase the operating pressure, but vent valve not to be fully close...

- Boiler Water System

Boiler Water SYSTEM We talked before about HITACHI Boiler Air and Flue gas system, we mentioned the characteristics of the boiler Air and flue gas & Parameters of operating Steam and waterAt this article we will make a focus on Water system at boiler....

- Boiler Air And Flue Gas System

Boiler AIR AND FLUE GAS SYSTEM "We talked before about HITACHI Boiler Overview (Steam Generator), we mentioned the characteristics of the boiler, Parameters of operating Steam and water.At this article we will make a focus on air and flue gas system...

Green Energy

Boiler STEAM SYSTEM

Boiler STEAM SYSTEM

-The boiler Steam system consists of SUPERHEATER, REHEATER AND BLOWDOWN SYSTEM

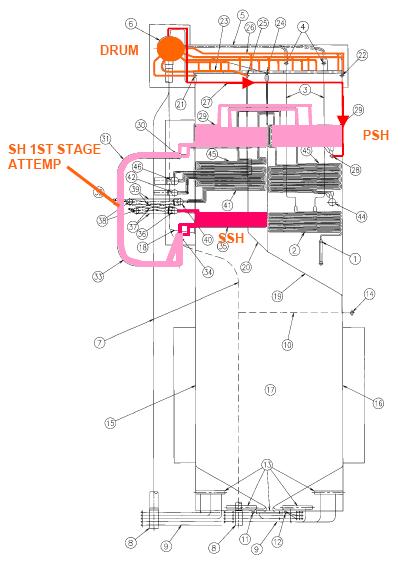

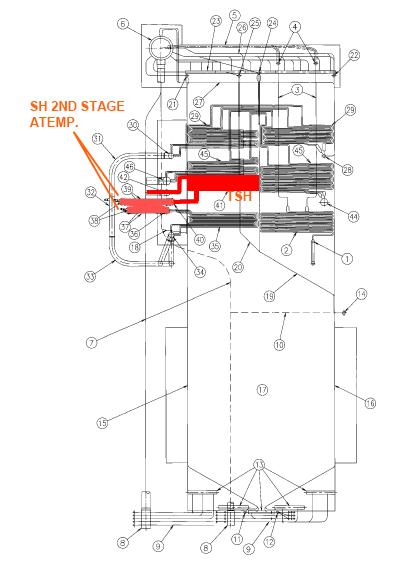

1) SUPERHEATER

-The saturated steam from the drum flows into three stages of superheaters. Steam is superheated up to rated temperature through primary, secondary and tertiary superheaters. Auxiliary steam and sootblower steam are extracted from the primary superheater outlet. Two stages of attemperators are provided between each superheater to control the boiler outlet main steam temperature. The boiler main steam stop valve is provided for the maintenance purpose such as hydrostatic test. Finally, superheated steam is supplied to the HP turbine from the boiler through the Main Steam Piping.

-Superheater spray water is supplied from the HP feedwater heater inlet. The superheater spray water piping distributes spray water to superheater first and second stage attemperators.

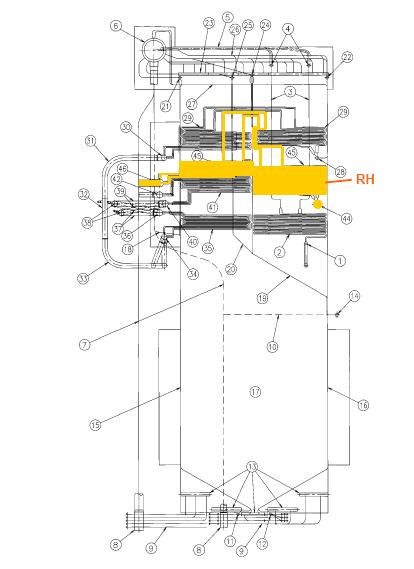

2) REHEATER

-The Cold-Reheat Piping conveys HP turbine exhaust steam from the HP turbine outlet to the reheater. The steam is reheated up to rated temperature through the reheater. The reheater outlet steam temperature is controlled by flue gas recirculation flow regulated by the Gas Recirculation Fans. Also an attemperator is provided at the Cold-Reheat Piping to control the reheater outlet steam temperature in abnormal condition. Then, reheated steam is supplied to the IP/LP turbine from the reheater through the Hot-Reheat Piping.

-Reheater spray water is supplied from middle stage of boiler feedwater pumps. The reheater spray water piping supplies spray water to reheater attemperator.

3) BLOWDOWN & DRAIN SYSTEM

-Continuous blowdown from the drum flows into the blowdown flash tank and is separated into steam and drain. Flashed steam is collected to the deaerator through the vent line. And separated drain is discharged into the atmospheric blowdown tank. The blowdown flash tank level control valve controls the blowdown flash tank water level. Safety valve is installed at the blowdown flash tank to prevent the tank from the overpressure.

-The atmospheric blowdown tank collects drain from the boiler pressure parts, startup blowoff line of the drum, the soot blowing system and the blowdown flash tank. Atmospheric blowdown tank separates the above drains into steam and water, Flashed steam is discharged to atmosphere through the vent line with silencer, And separated drain is discharged to the blowdown sump through attemperator.

“This description is FOR HITACHI Steam Generator “

- Boiler Drum Roles

BOILER DRUM ROLES - Steam drums are used on recirculating boilers that operate at subcritical pressures. The primary purpose of the steam drum is to separate the saturated steam from the steam-water mixture that leaves the heat transfer surfaces...

- Boiler Steam Purity

BOILER STEAM PURITY - It is important that the steam leaving the boiler drum should be free from impurities which could be deposited in the superheater or the turbine. - Such impurities may arise from two distinct causes, one being the property...

- Deaerator ( Part 2 )

DEAERATOR ( PART 2 ) OPERATION PROCEDURES ** Pre-start checks and operations(1) Vent valve shall be wide open.(At low load start, it may be necessary to throttle valve slightly to increase the operating pressure, but vent valve not to be fully close...

- Boiler Water System

Boiler Water SYSTEM We talked before about HITACHI Boiler Air and Flue gas system, we mentioned the characteristics of the boiler Air and flue gas & Parameters of operating Steam and waterAt this article we will make a focus on Water system at boiler....

- Boiler Air And Flue Gas System

Boiler AIR AND FLUE GAS SYSTEM "We talked before about HITACHI Boiler Overview (Steam Generator), we mentioned the characteristics of the boiler, Parameters of operating Steam and water.At this article we will make a focus on air and flue gas system...