Green Energy

- Boiler Drum Roles

BOILER DRUM ROLES - Steam drums are used on recirculating boilers that operate at subcritical pressures. The primary purpose of the steam drum is to separate the saturated steam from the steam-water mixture that leaves the heat transfer surfaces...

- Boiler (master Fuel Trip)

Steam Generator ( boiler ) is very important equipment at thermal power units , Boiler is the steam supply for the unit to rotate the turbine's rotor , hence produce electricity at Generator's stator. Boiler usually equipped with solar and Main...

- Boiler Steam System

Boiler STEAM SYSTEM -The boiler Steam system consists of SUPERHEATER, REHEATER AND BLOWDOWN SYSTEM 1) SUPERHEATER-The saturated steam from the drum flows into three stages of superheaters. Steam is superheated up to rated temperature through primary,...

- Boiler Air And Flue Gas System

Boiler AIR AND FLUE GAS SYSTEM "We talked before about HITACHI Boiler Overview (Steam Generator), we mentioned the characteristics of the boiler, Parameters of operating Steam and water.At this article we will make a focus on air and flue gas system...

- Boiler Control Theory (feed Water Control)

Boiler Control Theory (Feed water Control) The feed water is controlled to keep the drum level . Water-level controls continuously monitor the level of water in a steam boiler in order to control the flow of feed water into the boiler and to protect...

Green Energy

Boiler Water SYSTEM

Boiler Water SYSTEM

We talked before about HITACHI Boiler Air and Flue gas system, we mentioned the characteristics of the boiler Air and flue gas & Parameters of operating Steam and water

At this article we will make a focus on Water system at boiler.

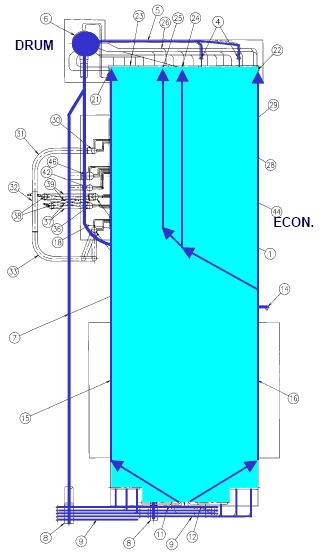

-The boiler Water system consists of ECONOMIZER AND DRUM & FURNACE WATER WALL.

1) ECONOMIZER

-Feedwater is supplied from the feedwater system to the boiler and is preheated by the economizer, Feedwater quality shall be properly controlled by the feedwater chemical treatment system. The economizer is situated at downstream of the reheater located in back end of the boiler.

-Since sufficient feedwater is not supplied into the economizer though the heat is absorbed from flue gas at the boiler start-up and low load operation, steaming may occur in the economizer. Therefore the economizer recirculation line is provided between the furnace downcomer and the economizer inlet feedwater piping. This line provides the recirculation flow between the drum, the downcomer and the economizer so as to prevent steaming in the economizer. Economizer recirculation valve is only opened at initial stage of the boiler start-up.

2) DRUM & FURNACE WATER WALL

-Feedwater preheated in the economizer is supplied to the drum. At the drum, water flows downward through the downcomer by gravity, and then flows into the furnace water wall. Steam is generated at the furnace water wall and water/steam mixture flows upward to the drum because of its small gravity. In this way, natural circulation is formed at drum, downcomer and furnace water wall.

-Drum water is treated by the phosphate injection system. And the drum has the continuous blowdown valve to discharge suspended solid from the drum water during normal operation. The drum also has cyclone separators and scrubber to separate the water from saturated steam. The startup blowoff valves are provided to the drum to handle the swelling phenomenon during the boiler start-up period.

“This description is FOR HITACHI Steam Generator “

- Boiler Drum Roles

BOILER DRUM ROLES - Steam drums are used on recirculating boilers that operate at subcritical pressures. The primary purpose of the steam drum is to separate the saturated steam from the steam-water mixture that leaves the heat transfer surfaces...

- Boiler (master Fuel Trip)

Steam Generator ( boiler ) is very important equipment at thermal power units , Boiler is the steam supply for the unit to rotate the turbine's rotor , hence produce electricity at Generator's stator. Boiler usually equipped with solar and Main...

- Boiler Steam System

Boiler STEAM SYSTEM -The boiler Steam system consists of SUPERHEATER, REHEATER AND BLOWDOWN SYSTEM 1) SUPERHEATER-The saturated steam from the drum flows into three stages of superheaters. Steam is superheated up to rated temperature through primary,...

- Boiler Air And Flue Gas System

Boiler AIR AND FLUE GAS SYSTEM "We talked before about HITACHI Boiler Overview (Steam Generator), we mentioned the characteristics of the boiler, Parameters of operating Steam and water.At this article we will make a focus on air and flue gas system...

- Boiler Control Theory (feed Water Control)

Boiler Control Theory (Feed water Control) The feed water is controlled to keep the drum level . Water-level controls continuously monitor the level of water in a steam boiler in order to control the flow of feed water into the boiler and to protect...