Green Energy

- Feed Forward Control Loops

Feed Forward Control Loops -A feedback control loop is reactive in nature and represents a response to the effect of a load change or upset. A feedforward control loop, on the other hand, responds directly to load changes and thus provides improved...

- Cascade Control Loops

Cascade Control Loops -The general concept of cascade control is to place one feedback loop inside another. In effect, one takes the process being controlled and finds some intermediate variable within the process to use as the set point for the main...

- On/off Control

On/Off Control - Suppose a process operator has the task of holding the temperature, T, near the desired temperature, Td, while making sure the tank doesn't overflow or the level get too low. The question is how the operator would cope with this...

- General Requirements Of A Control System

General Requirements of a Control System The primary requirement of a control system is that it be reasonably stable. In other words, its speed of response must be fairly fast, and this response must show reasonable damping. A control system must also...

- Advanced Process Controller (apc) For Controlling Steam Power Plant {part 2}.

Advantages of an Advanced Process Controller Figure 5 The APC-based unit control concept for main steam pressure control Figure 5 can be differentiated from the conventional unit control approach in several important ways: The APC is able...

Green Energy

Elements of a Process Control System

Elements of a Process Control System

INTRODUCTION

-The term automatic process control came into wide use when people learned to adapt automatic regulatory procedures to manufacture products or process material more efficiently. Such procedures are called automatic because no human (manual) intervention is required to regulate them.

-All process systems consist of three main factors or terms: the manipulated variables, disturbances, and the controlled variables. Typical manipulated variables are valve position, motor speed, damper position, or blade pitch. The controlled variables are those conditions, such as temperature, level, position, pressure, pH, density, moisture content, weight, and speed, that must be maintained at some desired value. For each controlled variable there is an associated manipulated variable. The control system must adjust the manipulated variables so the desired value or “set point” of the controlled variable is maintained despite any disturbances.

Elements of a Process Control System

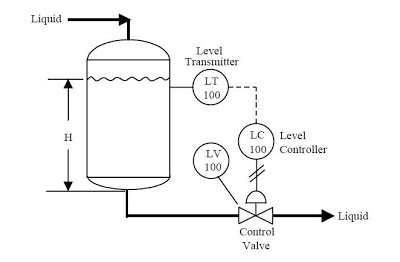

-The following figure illustrates the essential elements of a process control system. In the system shown, a level transmitter (LT), a level controller (LC), and a control valve (LV) are used to control the liquid level in a process tank. The purpose of this control system is to maintain the liquid level at some prescribed height (H) above the bottom of the tank. It is assumed that the rate of flow into the tank is random. The level transmitter is a device that measures the fluid level in the tank and converts it into a useful measurement signal, which is sent to a level controller. The level controller evaluates the measurement, compares it with a desired set point (SP), and produces a series of corrective actions that are sent to the control valve. The valve controls the flow of fluid in the outlet pipe to maintain a level in the tank.

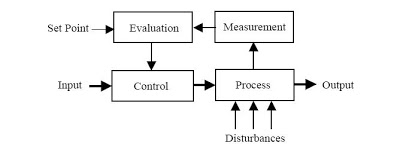

-Thus, a process control system consists of four essential elements: process, measurement, evaluation, and control. A block diagram of these elements is shown in the following figure. The diagram also shows the disturbances that enter or affect the process. If there were no upsets to a process, there would be no need for the control system. The figure also shows the input and output of the process and the set point used for control.

PROCESS

In general, a process consists of an assembly of equipment and material that is related to some manufacturing operation or sequence. In the example presented, the process whose liquid level is placed under control includes such components as a tank, the liquid in the tank, and the flow of liquid into and out of the tank, and the inlet and outlet piping. Any given process can involve many dynamic variables, and it may be desirable to control all of them. In most cases, however, controlling only one variable will be sufficient to control the process to within acceptable limits. One occasionally encounters a multivariable process in which many variables, some interrelated, require regulation.

MEASUREMENT

- To control a dynamic variable in a process, you must have information about the entity or variable itself. This information is obtained by measuring the variable.

- Measurement refers to the conversion of the process variable into an analog or digital signal that can be used by the control system. The device that performs the initial measurement is called a sensor or instrument. Typical measurements are pressure, level, temperature, flow, position, and speed. The result of any measurement is the conversion of a dynamic variable into some proportional information that is required by the other elements in the process control loop or sequence.

EVALUATION

- In the evaluation step of the process control sequence, the measurement value is examined, compared with the desired value or set point, and the amount of corrective action needed to maintain proper control is determined. A device called a controller performs this evaluation. The controller can be a pneumatic, electronic, or mechanical device mounted in a control panel or on the process equipment. It can also be part of a computer control system, in which case the control function is performed by software.

CONTROL

The control element in a control loop is the device that exerts a direct influence on the process or manufacturing sequence. This final control element accepts an input from the controller and transforms it into some proportional operation that is performed on the process. In most cases, this final control element will be a control valve that adjusts the flow of fluid in a process. Devices such as electrical motors, pumps, and dampers are also used as control elements.

------------------------------------------------------------------------------

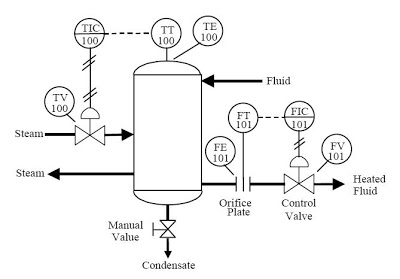

Process and Instrumentation Drawings

-In standard P&IDs, the process flow lines, such as process fluid and steam, are indicated with heavier solid lines than the lines that are used to represent the instrument. The instrument signal lines use special markings to indicate whether the signal is pneumatic, electric, hydraulic, and so on. two types of instrument signals are used: double cross-hatched lines denote the pneumatic signals to the steam control valve and the process outlet flow control valve, and a dashed line is used for the electrical control lines between various instruments. In process control applications, pneumatic signals are almost always 3 to 15 psig (i.e., pounds per square inch, gauge pressure), and the electric signals are normally 4 to 20 mA (milliamperes) DC (direct current).

- A balloon symbol with an enclosed letter and number code is used to represent the instrumentation associated with the process control loop. This letter and number combination is called an instrument identification or instrument tag number.

- The first letter of the tag number is normally chosen so that it indicates the measured variable of the control loop. In the sample P&ID shown, T is the first letter in the tag number that is used for the instruments in the temperature control loop. The succeeding letters are used to represent readout or passive function or an output function, or the letter can be used as a modifier. For example, the balloon in Figure marked TE represents a temperature element and that marked TIC is a temperature-indicating controller. The line across the center of the TIC balloon symbol indicates that the controller is mounted on the front of a main control panel. No line indicates a field-mounted instrument, and two lines means that the instrument is mounted in a local or field-mounted panel. Dashed lines indicate that the instrument is mounted inside the panel.

- Normally, sequences of three- or four-digit numbers are used to identify each loop. In our process example, we used loop numbers 100 and 101. Smaller processes use three-digit loop numbers; larger processes or complex manufacturing plants may require four or more digits to identify all the control loops.

- Special marks or graphics are used to represent process equipment and instruments. For example, in our P&ID example in Figure two parallel lines represent the orifice plate that is used to detect the discharge flow from the process heater.

- Feed Forward Control Loops

Feed Forward Control Loops -A feedback control loop is reactive in nature and represents a response to the effect of a load change or upset. A feedforward control loop, on the other hand, responds directly to load changes and thus provides improved...

- Cascade Control Loops

Cascade Control Loops -The general concept of cascade control is to place one feedback loop inside another. In effect, one takes the process being controlled and finds some intermediate variable within the process to use as the set point for the main...

- On/off Control

On/Off Control - Suppose a process operator has the task of holding the temperature, T, near the desired temperature, Td, while making sure the tank doesn't overflow or the level get too low. The question is how the operator would cope with this...

- General Requirements Of A Control System

General Requirements of a Control System The primary requirement of a control system is that it be reasonably stable. In other words, its speed of response must be fairly fast, and this response must show reasonable damping. A control system must also...

- Advanced Process Controller (apc) For Controlling Steam Power Plant {part 2}.

Advantages of an Advanced Process Controller Figure 5 The APC-based unit control concept for main steam pressure control Figure 5 can be differentiated from the conventional unit control approach in several important ways: The APC is able...