Green Energy

- "umm, No, Not Really.”

Obamacare call center operator, called by Sean Hannity today, and asked if anyone liked the setup, on the phone or the website.From RCP:At the top of his radio program today, Sean Hannity called in to an Obamacare call center. Hannity was able to get...

- Keeping Control Of Drum Levels

Keeping Control of Drum Levels “THIS ARTICLE GIVES US DIFFERENT TECHNIQUES ABOUT BOILER CONTROL ESPECIALLY DRUM LEVEL CONTROL,” -Power plants are designed to operate for decades, provided they undergo regular repair, upgrade and improvement....

- Elements Of A Process Control System

Elements of a Process Control System INTRODUCTION-The term automatic process control came into wide use when people learned to adapt automatic regulatory procedures to manufacture products or process material more efficiently. Such procedures are called...

- Boiler Steam System

Boiler STEAM SYSTEM -The boiler Steam system consists of SUPERHEATER, REHEATER AND BLOWDOWN SYSTEM 1) SUPERHEATER-The saturated steam from the drum flows into three stages of superheaters. Steam is superheated up to rated temperature through primary,...

- The Celsius, Fahrenheit, And Kelvin Temperature Scales

Tc = T - 273.15 This Equation shows that the Celsius temperature Tc is shifted from the absolute (Kelvin) temperature T by 273.15°. Because the size of a degree is the same on the two scales, a temperature difference of 5°C is equal...

Green Energy

On/Off Control

On/Off Control

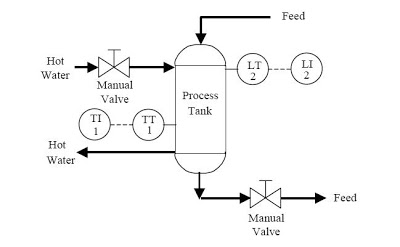

- Suppose a process operator has the task of holding the temperature, T, near the desired temperature, Td, while making sure the tank doesn't overflow or the level get too low. The question is how the operator would cope with this task over a period of time. He or she would manually adjust the hot water inlet valve (HV-1) to maintain the temperature and occasionally adjust the outlet valve (HV-2) to maintain the correct level in the tank.

- The operator would face several problems, however. Both indicators would have to be within the operator's view, and the manual valves would have to be close to the operator and easy to adjust.

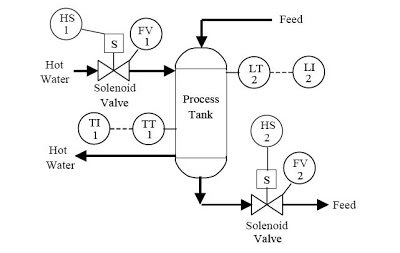

- To make the operator's work easier, suppose we installed electrically operated solenoid valves in place of the manual valves, as shown in the next figure. We can also install two hand switches (HS-1 and HS-2) so the solenoid valves can be operated from a common location. The valves can assume two states, either fully open (on) or fully closed (off). This type of control is called two-position or on/off control.

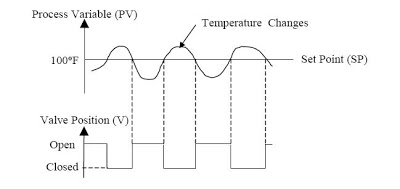

- Assume for the moment that the level is holding steady and that the main concern is controlling temperature. The operator has been told to keep the temperature of the fluid in the tank at 100°F. He compares the reading of the temperature indicator with the selected set point of 100°F. The operator closes the hot water valve when the temperature of the fluid in the tank rises above the set point. Because of process dead time and lags the temperature will continue to rise before reversing and moving toward the set point. When the temperature falls below 100°F, the operator opens the hot water valve. Again, dead time and lags in the process create a delay before the temperature begins to rise. As it crosses the set point, the operator again shuts off the hot water, and the cycle repeats.

- This cycling is normal for a control system that uses on/off control. This limitation exists because it’s impossible for the operator to control the process exactly with only two options.

This on/off type of control can be expressed mathematically as follows:

e = PV – SP

In the on/off control mode, the valve is open valve when the error (e) is positive (+), and the valve is closed when e is negative (–).

- "umm, No, Not Really.”

Obamacare call center operator, called by Sean Hannity today, and asked if anyone liked the setup, on the phone or the website.From RCP:At the top of his radio program today, Sean Hannity called in to an Obamacare call center. Hannity was able to get...

- Keeping Control Of Drum Levels

Keeping Control of Drum Levels “THIS ARTICLE GIVES US DIFFERENT TECHNIQUES ABOUT BOILER CONTROL ESPECIALLY DRUM LEVEL CONTROL,” -Power plants are designed to operate for decades, provided they undergo regular repair, upgrade and improvement....

- Elements Of A Process Control System

Elements of a Process Control System INTRODUCTION-The term automatic process control came into wide use when people learned to adapt automatic regulatory procedures to manufacture products or process material more efficiently. Such procedures are called...

- Boiler Steam System

Boiler STEAM SYSTEM -The boiler Steam system consists of SUPERHEATER, REHEATER AND BLOWDOWN SYSTEM 1) SUPERHEATER-The saturated steam from the drum flows into three stages of superheaters. Steam is superheated up to rated temperature through primary,...

- The Celsius, Fahrenheit, And Kelvin Temperature Scales

Tc = T - 273.15 This Equation shows that the Celsius temperature Tc is shifted from the absolute (Kelvin) temperature T by 273.15°. Because the size of a degree is the same on the two scales, a temperature difference of 5°C is equal...