Green Energy

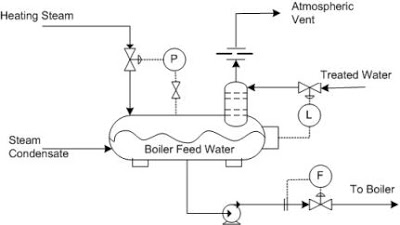

You noticed that just below the heater, is a relatively large feedwater tank (Storage Tank) which allows sufficient water for rapid load variations.

- Boiler Drum Roles

BOILER DRUM ROLES - Steam drums are used on recirculating boilers that operate at subcritical pressures. The primary purpose of the steam drum is to separate the saturated steam from the steam-water mixture that leaves the heat transfer surfaces...

- Boiler Steam System

Boiler STEAM SYSTEM -The boiler Steam system consists of SUPERHEATER, REHEATER AND BLOWDOWN SYSTEM 1) SUPERHEATER-The saturated steam from the drum flows into three stages of superheaters. Steam is superheated up to rated temperature through primary,...

- Boiler Water System

Boiler Water SYSTEM We talked before about HITACHI Boiler Air and Flue gas system, we mentioned the characteristics of the boiler Air and flue gas & Parameters of operating Steam and waterAt this article we will make a focus on Water system at boiler....

- Boiler Air And Flue Gas System

Boiler AIR AND FLUE GAS SYSTEM "We talked before about HITACHI Boiler Overview (Steam Generator), we mentioned the characteristics of the boiler, Parameters of operating Steam and water.At this article we will make a focus on air and flue gas system...

- Can Your Boiler Feed Pump Handle A Deaerator Pressure Transient?

Can Your Boiler Feed Pump Handle a Deaerator Pressure Transient? “This is part of an article talking about the importance of DA and BFP positions at power plant “ In a typical steam power plant, the boiler feedwater (BFW) pump takes suction...

Green Energy

Open Feed Water Heater (Deaerator)

Open Feed Water Heater (Deaerator)

An open feadwater heater , also called direct-contact and deaerating (DA) heater , is one that heats the feedwater by directly mixing it with bled steam from the turbine. Usually only one DA is used at Power Plant.

Because the pressure in such a heater can’t exceed the turbine pressure at the point of extraction, a pump (Main Boiler Feed Water Pump) must follow the heater. The confluence of steam and water flows makes possible the efficient removal of noncondensables as well as the heating of the feedwater.

The DA heater is usually positioned in the feedwater line at a pressure to prevent air inleakage and at a temperature at which Oxygen retention is least likely. Most DA heaters are designed for Oxygen concentration in the outlet feedwater below 0.005Cm3/L

The DA outlet feedwater is at or near saturation. Pumping saturated water results in cavitation because of the pressure drop below saturated pressure, thus causing flashing on the back side of pump vanes. The DA heater is therefore usually positioned in the powerplant steam-generator house high above its pump by perhaps 60 ft. This provides sufficient pump inlet pressure to render the saturated water compressed (or subcooled) and prevents cavitations.

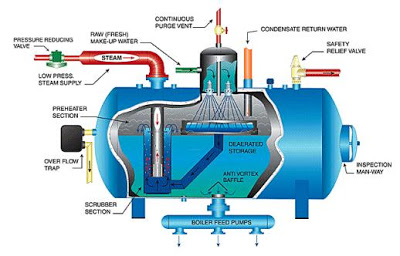

There are three types of DA heaters for industrial and utility use.

1) Spray-Type deaerators .

In this type the feedwater enters the heater through nozzles that spray it into the extraction-steam-filled heater space. The water is heated and scrubbed to release the noncondensables gases. A second agitation of the now-heated feedwater by another steam flow is provided by an internal baffling system.

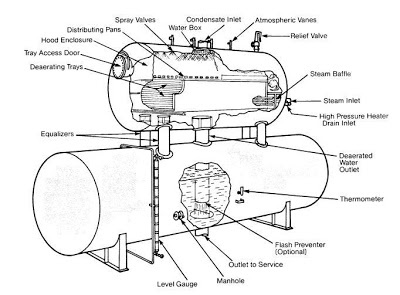

2) Tray-Type deaerators.

Here the feedwater is directed onto a series of cascading horizontal trays. It falls in sheets or tubes from tray to tray and comes into contact with rising extraction steam admitted from the bottom of the tray system. As scrubbing occurs and noncondensables gases and some steam rise, they come into contact with colder water, resulting in a reduced volume of high concentration of noncondensables to vent into the atmosphere.

3) Combination spray-tray deaerator

In this type, the feedwater is first sprayed into a steam-filled space, then made to cascade down trays. This combination type with horizontal stainless steel trays is currently preferred by utilities.

- Boiler Drum Roles

BOILER DRUM ROLES - Steam drums are used on recirculating boilers that operate at subcritical pressures. The primary purpose of the steam drum is to separate the saturated steam from the steam-water mixture that leaves the heat transfer surfaces...

- Boiler Steam System

Boiler STEAM SYSTEM -The boiler Steam system consists of SUPERHEATER, REHEATER AND BLOWDOWN SYSTEM 1) SUPERHEATER-The saturated steam from the drum flows into three stages of superheaters. Steam is superheated up to rated temperature through primary,...

- Boiler Water System

Boiler Water SYSTEM We talked before about HITACHI Boiler Air and Flue gas system, we mentioned the characteristics of the boiler Air and flue gas & Parameters of operating Steam and waterAt this article we will make a focus on Water system at boiler....

- Boiler Air And Flue Gas System

Boiler AIR AND FLUE GAS SYSTEM "We talked before about HITACHI Boiler Overview (Steam Generator), we mentioned the characteristics of the boiler, Parameters of operating Steam and water.At this article we will make a focus on air and flue gas system...

- Can Your Boiler Feed Pump Handle A Deaerator Pressure Transient?

Can Your Boiler Feed Pump Handle a Deaerator Pressure Transient? “This is part of an article talking about the importance of DA and BFP positions at power plant “ In a typical steam power plant, the boiler feedwater (BFW) pump takes suction...